More At The Farmhouse

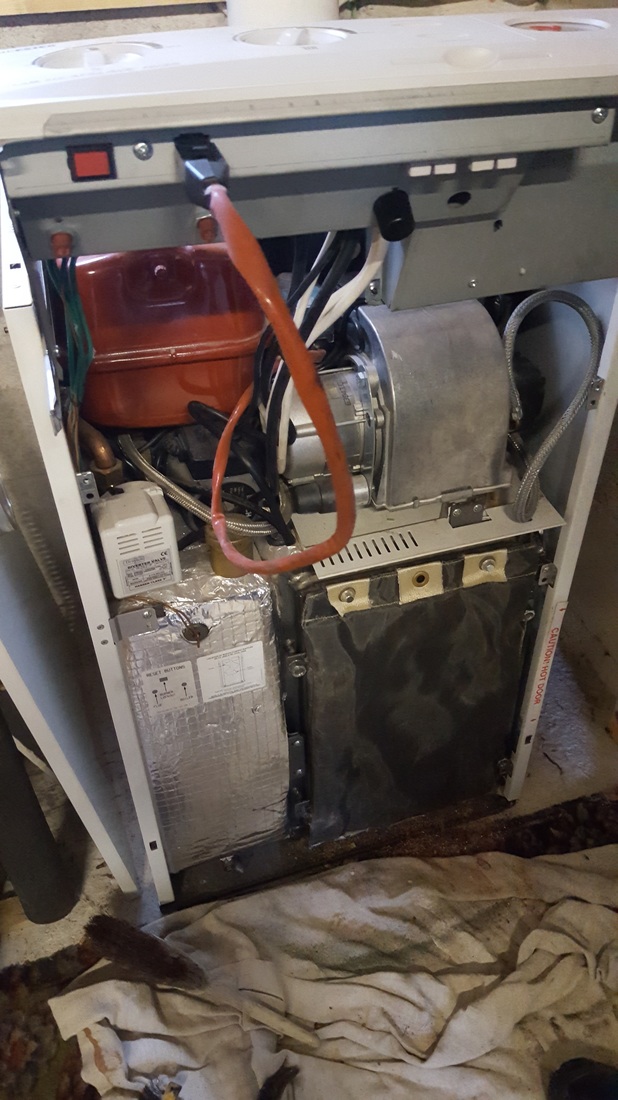

| Since we last updated you, we have continued our work at the Farmhouse. We have now finished the first half of the house and are on to the second half. Around the edge of the Farmhouse is an old tunnel which we facilitated for getting the pipework from A to B without being on display. Whilst this created a great finish for the pipework you could see, it was certainly a tight squeeze! |

A Small Building Job

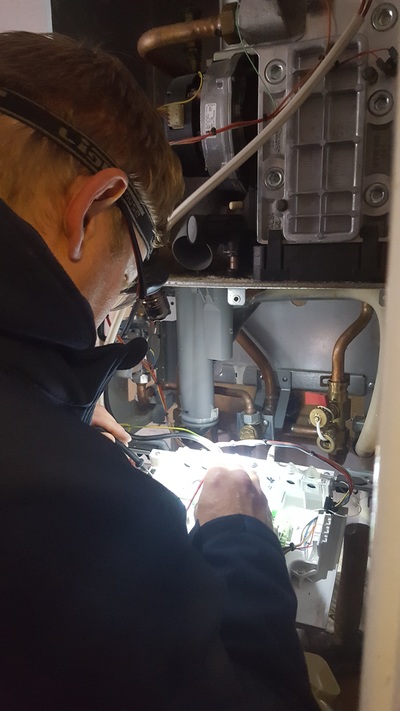

| Over a period of 2 weeks, we worked hard to convert a small, impractical utility room into a much larger one. We did this by building a new wall further along in the garage than the current wall, knocking down the wall that was in place, and making an archway into what was the previous utility. We also knocked down a small wall in the back of a cupboard that backed onto the garage to create a new entrance into the utility. With some careful plastering, tiling and decorating, the utility was complete! (please note the curves in the archway are due to the panoramic shot of the camera) |